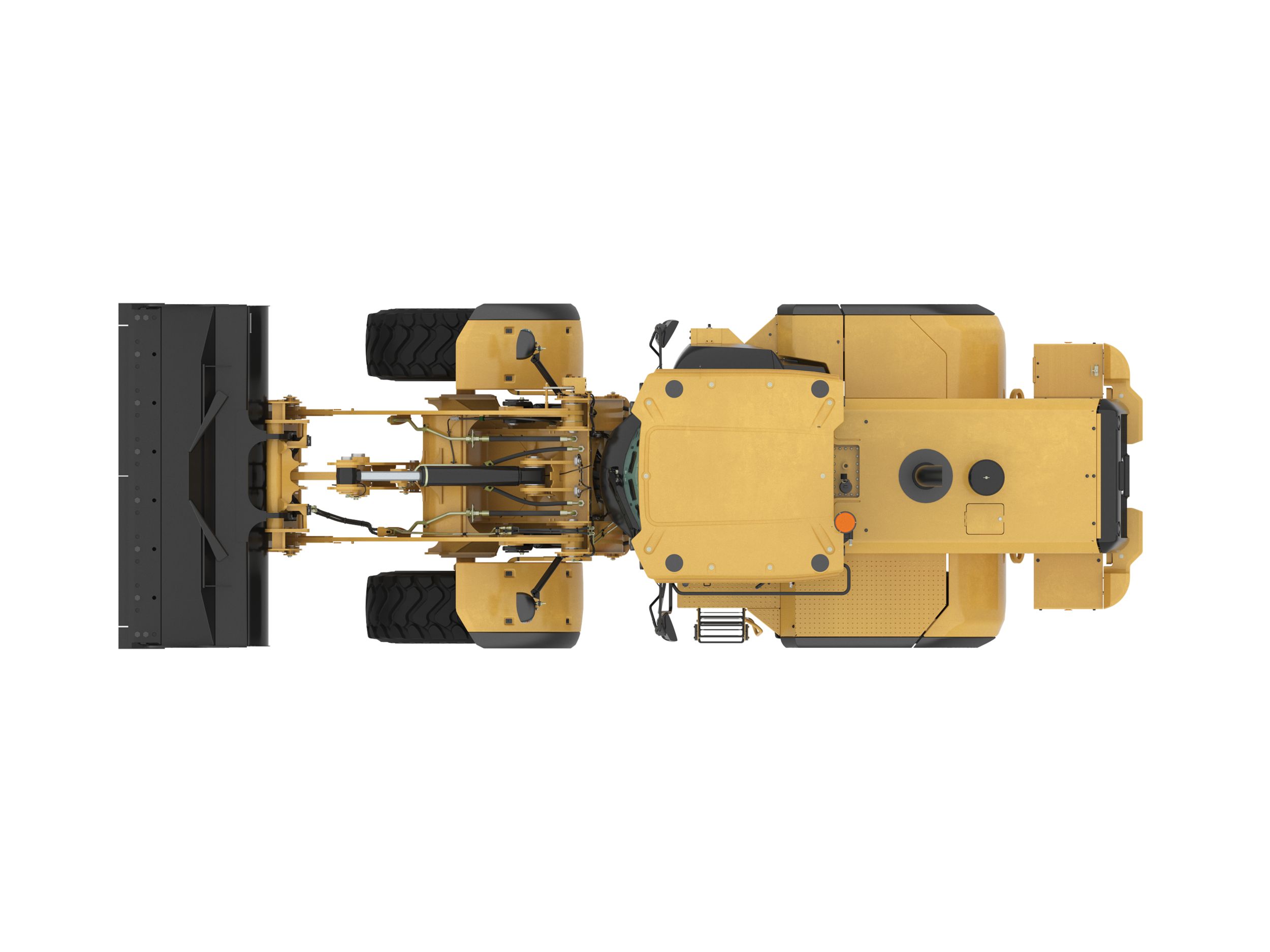

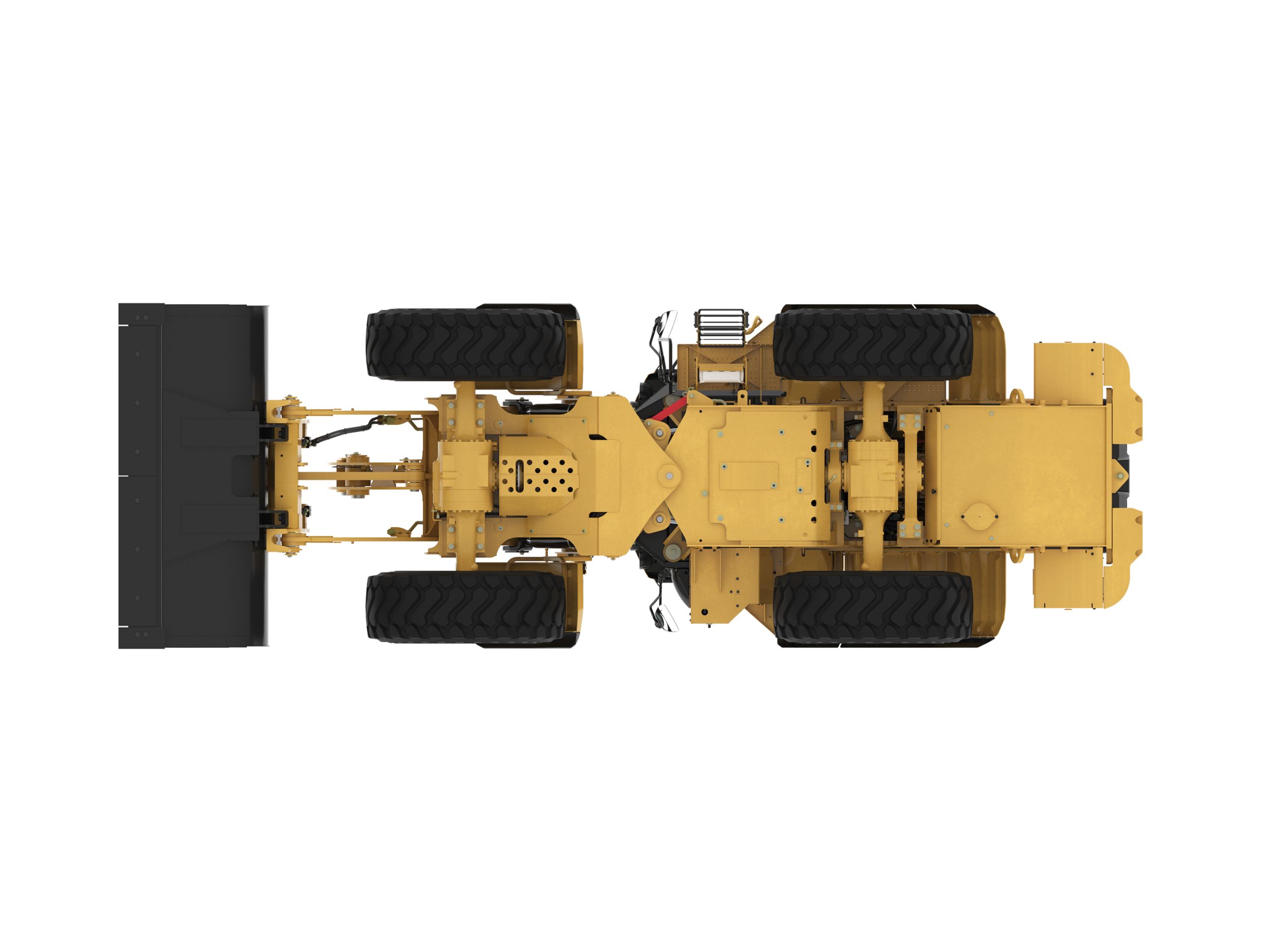

926M Small Wheel Loader

The Cat 926M Small Wheel Loader sets the standard for productivity, fuel efficiency and operator comfort. The improved optimized Z-bar loader linkage delivers the quick loading performance of a traditional Z-bar with the parallelism and load handling capability of a tool carrier. A high torque, low speed C7.1 ACERT engine works in concert with an intelligent hystat power train to deliver fuel efficiency as standard. Meets Tier 4 Final/Stage V emission standards with an environmentally friendly, Clean Emission Module designed to manage itself so you can concentrate on your work. Experience the new industry benchmark.

| Maximum Gross Power | 125 kW |

|---|---|

| Engine Model | Cat C7.1** |

| Displacement (Performance Power Mode: Speed Range 1-4) | 7.01 l |

| Displacement (Standard Power Mode: Speed Range 1-3*) | 7.01 l |

| Maximum Gross Power - 1,600 rpm - ISO 14396 (DIN) (Standard Power Mode: Range 1-3*) | 162 mhp |

| Maximum Gross Power - 1,600 rpm - ISO 14396 (Standard Power Mode: Range 1-3*) | 119 kW |

| Maximum Gross Power - 1,800 rpm - ISO 14396 (DIN) (Performance Power Mode: Range 1-4) | 170 mhp |

| Maximum Gross Power - 1,800 rpm - ISO 14396 (Performance Power Mode: Range 1-4) | 125 kW |

| Maximum Gross Torque - ISO 14396 (Performance Power Mode: Range 1-4) | 815 N·m |

| Maximum Gross Torque - ISO 14396 (Standard Power Mode: Range 1-3*) | 795 N·m |

| Maximum Net Torque - ISO 9249:2007 (Performance Power Mode: Range 1-4) | 796 N·m |

| Maximum Net Torque - ISO 9249:2007 (Standard Power Mode: Range 1-3*) | 776 N·m |

| Maximum Net Torque - SAE J1349 (Performance Power Mode: Range 1-4) | 797 N·m |

| Maximum Net Torque - SAE J1349 (Standard Power Mode: Range 1-3*) | 777 N·m |

| Note (1) | Net power ratings are tested at the reference conditions for the specified standard and denote power available at the flywheel when the engine is equipped with alternator, air cleaner, emission components and fan at specified speed. |

| Note (2) | No derating required up to 3000 m (10,000 ft) altitude. Auto derate protects hydraulic and transmission systems. |

| Note (4) | **The Cat C7.1 engine meets Tier 4 Final/Stage V off-highway emission standards. |

| Rated Net Power - 1,600 rpm - ISO 9249 (DIN) at Minimum Fan Speed (Standard Power Mode: Range 1-3*) | 158 mhp |

| Rated Net Power - 1,600 rpm - ISO 9249 at Minimum Fan Speed (Standard Power Mode: Range 1-3*) | 116 kW |

| Rated Net Power - 1,600 rpm - SAE J1349 at Minimum Fan Speed (Standard Power Mode: Range 1-3*) | 116 kW |

| Rated Net Power - 1,800 rpm - ISO 9249 (DIN) at Minimum Fan Speed (Performance Power Mode: Range 1-4) | 166 mhp |

| Rated Net Power - 1,800 rpm - ISO 9249 at Minimum Fan Speed (Performance Power Mode: Range 1-4) | 122 kW |

| Rated Net Power - 1,800 rpm - SAE J1349 at Minimum Fan Speed (Performance Power Mode: Range 1-4) | 122 kW |

| Note (3) | *Range 4 power and torque is equal to Performance Mode with Caterpillar Power by Range technology. |

| Operating Weight | 12789 kg |

|---|

| Bucket Capacities | 1.9-5.0 m3 (2.5-6.5 yd3) |

|---|---|

| Bucket Capacities - General Purpose | 1.9-2.5 m³ (2.5-3.2 yd³) |

| Bucket Capacities - Light Material | 3.1-5.0 m³ (4.0-6.5 yd³) |

| Front | Fixed; Locking differential (standard) |

|---|---|

| Rear | Oscillating ±11 degrees; Open differential (standard); Limited slip differential (optional) |

| Fuel Tank | 195 l |

|---|---|

| Cooling System | 30 l |

| Note | DEF used in Cat SCR systems must meet the requirements outlined in the International Organization for Standardization (ISO) standard 22241-1. |

| Diesel Exhaust Fluid (DEF) Tank | 19 l |

| Engine Crankcase | 20 l |

| Front Axles | 26 l |

| Hydraulic System - Including Tank | 160 l |

| Hydraulic Tank | 90 l |

| Rear Axles | 25 l |

| Transmission - Gear Box | 8.5 l |

| ROPS | ISO 3471:2008 |

|---|---|

| FOPS | ISO 3449:2005 Level II |

| Note (1) | Cab and Rollover Protective Structures (ROPS) are standard in North America and Europe. |

| Note (2) |

The declared dynamic operator sound pressure levels per ISO 6396:2008*, when properly installed and maintained, are: – Standard cab: 68 ±3 dB(A) – Deluxe cab: 66 ±2 dB(A) |

| Note (3) | *The measurements were conducted with the cab doors and windows closed and at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds. |

| Air Conditioning | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.9 kg of refrigerant which has a CO2 equivalent of 2.717 metric tonnes. |

|---|

| Hydraulic Cycle Time - Performance Mode at 1,800 rpm - Dump, at Maximum Lift Height | 1.5 s |

|---|---|

| Hydraulic Cycle Time - Performance Mode at 1,800 rpm - Float Down, Maximum Lift to Ground Level | 2.6 s |

| Hydraulic Cycle Time - Performance Mode at 1,800 rpm - Raise, Ground Level to Maximum Lift | 5.5 s |

| Hydraulic Cycle Time - Performance Mode at 1,800 rpm - Total Cycle Time | 9.5 s |

| Hydraulic Cycle Time - Standard Mode at 1,600 rpm - Dump, at Maximum Lift Height | 1.7 s |

| Hydraulic Cycle Time - Standard Mode at 1,600 rpm - Float Down, Maximum Lift to Ground Level | 2.6 s |

| Hydraulic Cycle Time - Standard Mode at 1,600 rpm - Raise, Ground Level to Maximum Lift | 6.2 s |

| Hydraulic Cycle Time - Standard Mode at 1,600 rpm - Total Cycle Time | 10.5 s |

| Maximum Flow - Implement Pump | 150 l/min |

| Maximum Flow - Implement Pump - 3rd Function Maximum Flow* | 150 l/min |

| Maximum Flow - Implement Pump - 4th Function Maximum Flow* | 150 l/min |

| Maximum Working Pressure - Implement Pump | 26000 kPa |

| Note (1) | *3rd and 4th function flow is fully adjustable from 20% to 100% of maximum flow through the secondary display, when equipped. |

| Relief Pressure - Tilt Cylinder | 28000 kPa |

| Relief Pressure - Tilt Cylinder - 3rd and 4th Function Maximum Working Pressure | 26000 kPa |

| Relief Pressure - Tilt Cylinder - 3rd and 4th Function Relief Pressure | 28000 kPa |

| Average Exterior Sound Pressure (ISO 6395:2008) | 101 dB(A) |

|---|---|

| Note (1) | European Union Directive “2000/14/EC.” |

| Operator Sound Pressure (ISO 6396:2008) | 72 dB(A) |

| Maximum Flow - Steering Pump | 130 l/min |

|---|---|

| Maximum Steering Torque - 0° (Straight Machine) | 50375 N·m |

| Maximum Steering Torque - 40° (Full Turn) | 37620 N·m |

| Maximum Working Pressure - Steering Pump | 24130 kPa |

| Number of Steering Wheel Turns - Full Left to Full Right or Full Right to Full Left | 3.5 turns |

| Steering Articulation Angle - Each Direction | 40° |

| Steering Cycle Times - Full Left to Full Right - At 1,800 rpm: 90 rpm Steering Wheel Speed | 2.4 s |

| Note (1) | Other tire choices are available. Contact your Cat dealer for details. |

|---|---|

| Note (2) | In certain applications, the loader’s productive capabilities may exceed the tire’s tonnes-km/h (ton-mph) capabilities. |

| Note (3) | Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model. |

| Other Choices Include | 20.5 R25, radial (L-2); 20.5 R25, radial (L-5); 20.5-25 12PR (L-2); 20.5-25 12PR (L-3); 20.5-25 16PR (L-5); 17.5 R25, radial (L-2); 17.5 R25, radial (L-3); 17.5 R25, radial (L-5); 550/65 R25 radial (L-3); Skidder/Agriculture |

| Standard Size | 20.5 R25, radial (L-3) |

| Forward and Reverse - Range 1* | 1-13 km/h (0.6-8 mph) |

|---|---|

| Forward and Reverse - Range 2 | 13 km/h |

| Forward and Reverse - Range 3 | 27 km/h |

| Forward and Reverse - Range 4 | 40 km/h |

| Note | *Creeper control allows maximum speed range adjustability from 1 km/h (0.6 mph) to 13 km/h (8 mph) in Range 1 through the secondary display, when equipped. Factory default is 7 km/h (4.4 mph). |

| Recyclability | 94% |

|---|

Ask Quotation

Usados